Print custom parts locally and efficiently.

High quality surgical guides, educational models, and medical tools.

Increase throughput.

With Array, you’ll gain access to parallelized production. You and your team will be able to print multiple jobs at the same time, and have your printers running 24 hours/day. One Array gives you the equivalent throughput of 12 individual 3D printers.

Multi-material 3D printing.

Access the ultimate level of flexibility in your printed output by harnessing Mosaic’s proprietary Palette X technology. Create educational models highlighting certain components in multiple colors and surgical guides with geometric freedom due to soluble support material.

Central Project Management (Software)

Unlock scaled 3D printing for your team. Canvas Teams will manage the submission and approval process, notifying your team when their print jobs are completed. Array’s Robotic System will print multiple jobs without the need for you to change out print beds, or swap out materials giving you the highest output with the lowest time requirement.

%20(1650%20%C3%97%201850%20px)%20(3).png?width=1783&height=2000&name=Establish%20project%20guidelines%20(1550%20%C3%97%201850%20px)%20(1650%20%C3%97%201850%20px)%20(3).png)

Featured Case Study

PolyUnity Tech Inc.

Mosaic recently flew out to beautiful Newfoundland to speak with PolyUnity Tech Inc. about 3D printing applications in healthcare and to learn about their use-case for our Element printer.

Initially, Element provided a larger, reliable and robust platform for addressing their FFF printing needs. But soon other features like remote operation, high-temperature printing, and an expanding network of materials, prove valuable in allowing PolyUnity to tackle an ever-changing list of jobs requested by healthcare customers.

Vital Surgical Aids with FFF

%20(2560%20%C3%97%20800%20px)%20(2560%20%C3%97%202000%20px)%20(5).png?width=400&height=313&name=Untitled%20(2560%20%C3%97%201000%20px)%20(2560%20%C3%97%20800%20px)%20(2560%20%C3%97%202000%20px)%20(5).png)

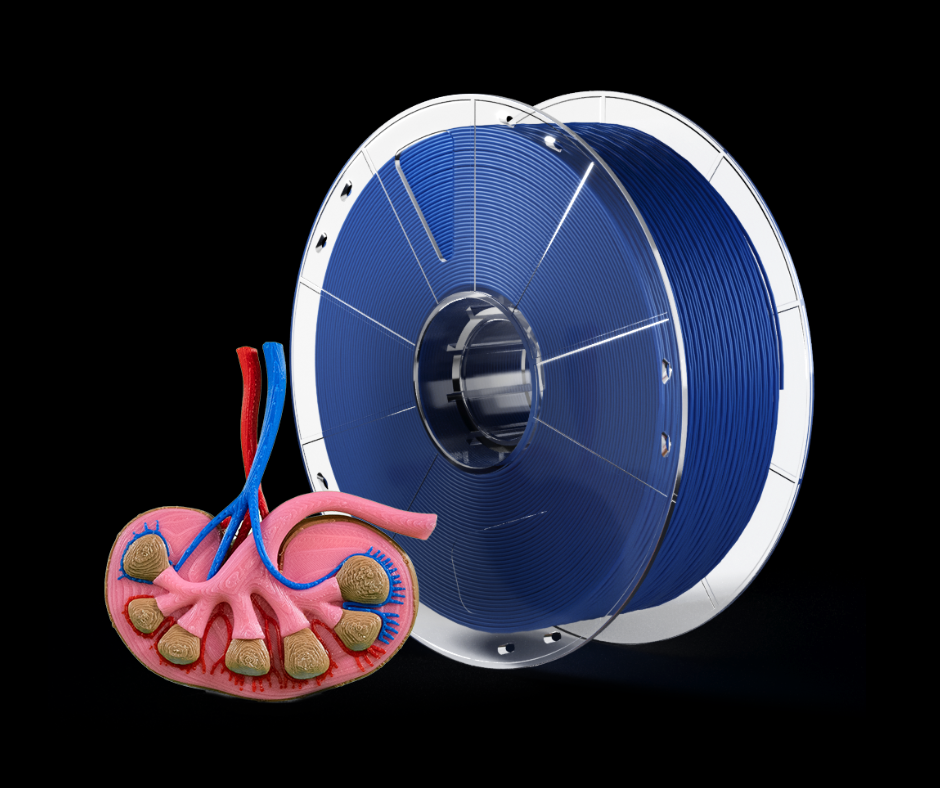

With Array and Element, you are able to efficiently print multicolor, multi-material models and surgical guides.

Increasingly, surgeons are utilizing data from CT and MRI scans to help construct accurate 3D images of their patients. These are then 3D printed and used to help plan surgeries. This is especially beneficial during intricate procedures that require multi-specialty surgeons. Surgeons are able to sterilize their prints and take them into the operating room for visual reference and practice before performing surgery on their patients.

Learn more about the uses of 3D printing in healthcare by discovering our article with Mirai 3D Healthcare and Dr. Gonzalo Vitagliano, Head of Uro-Oncology and Urolaparoscopy at the Hospital Alemán of Buenos Aires.

I believe that 3D modeling for complex renal tumors has become vital in my daily practice. Surprises are usually fun; however, not in the operating room where safety is the primal goal. 3D modeling has revolutionized the way I perform laparoscopic surgery, taking away the element of surprise and replacing it for certainty. As such, my practice has become safer and more predictable.

- Dr. Vitagliano

.png)

Element HT

Office Scale | Versatile | Compact

Paired with Mosaic’s software Canvas, Element acts as a low volume, end to end orthotics production line. Element will fit on any desk and is perfect for a small or medium sized operation (with a current production rate of 5-50 prints per week). Element produces high quality, ready to ship parts, without the need for post-processing. With a focus on throughput and reliability, Element will serve your needs from day 1.

.png)

Array

Lab Scale | Automated | Low Labour

Array is a high volume automated production system, matching the throughput capabilities of approximately 10 desktop printers. Paired with Mosaic’s print management software Canvas, Array can produce hundreds of prints per week, while requiring minimal operator oversight. This, coupled with the ability to queue jobs remotely, makes Array an excellent fit for operations with larger quantities of orders to fulfill.

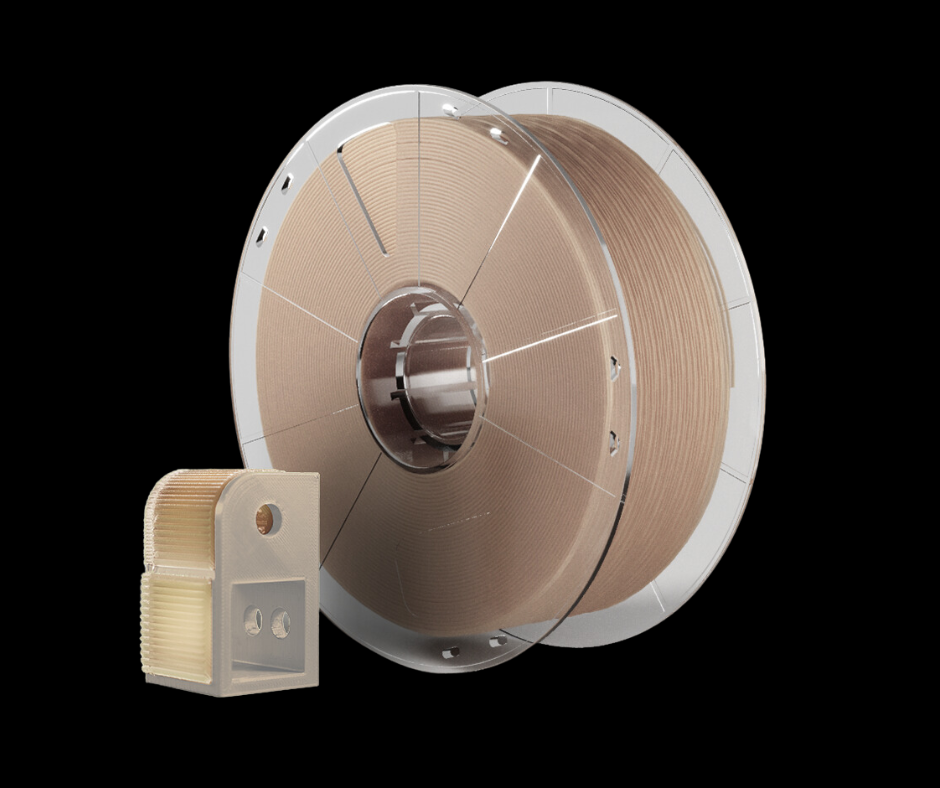

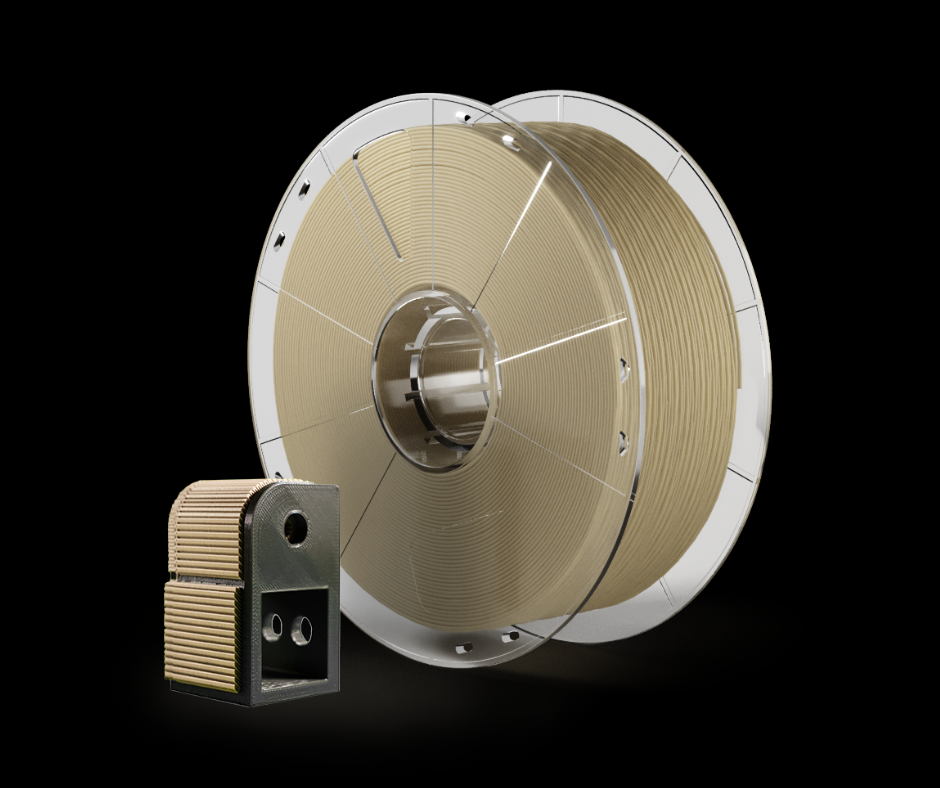

Materials Overview

Mosaic’s materials experts are on call to help you select the best material for each of your products.

Mosaic PEEK

A high performance engineering-grade thermoplastic. Strong, durable, and low flamability.

Mosaic Polypropylene

A lightweight material with excellent chemical and thermal resistance, dimensional stability, and little to no warping.

Mosaic ASA

An excellent and durable choice for end use parts. Heat and UV light resistant.

Mosaic Matrix (CF Nylon)

A proprietary blend of carbon fiber reinforced nylon, durable and optimized to yield parts with high aesthetic quality.

Learn More

Allow us to find a custom solution according to your business needs and objectives. Contact a member of our sales team directly by providing your information below.